Connections: How Weidmuller LUF 10.00 series interconnects help Dolby suspend your disbelief

/Connections: How Weidmuller LUF 10.00 series interconnects help Dolby suspend your disbelief

Now that we can go to movie theaters (sort of) and immerse ourselves in a full sight and sound experience with all the fixins’, the rogue engineer might wonder what it takes to deliver the perfect sound palette as the action unfolds onscreen. The audiophiles amongst us will focus on the sound, but it is the engineer that queries as to how a theater’s sound system delivers a perfect cacophonous symphony for each showing without the proverbial wheels coming off.

Most of us know that speakers vibrate as they emit sound, and the louder and lower sounds they emit in turn vibrate just about everything they can within their zone of influence including their very enclosures. Over time, the sustained barrage of sound vibrations will work fittings loose and wire connectors ajar.

So, how do we ensure critical speaker components stay connected for repeated movie showings? This is the very question Dolby Cinema Technology Engineer, Jerry Sommerfeld put to the engineers at Weidmuller. Sommerfeld and his team at Dolby were in the process of evaluating connectors for two new high performance loudspeaker series, which require reliable, easy-to-use, and rugged interconnects. Not missing a beat, Weidmuller ultimately recommended their high current, battle tested LUF terminal blocks (part of Weidmuller’s extended OMNIMATE family), which would grant Dolby’s systems years of service.

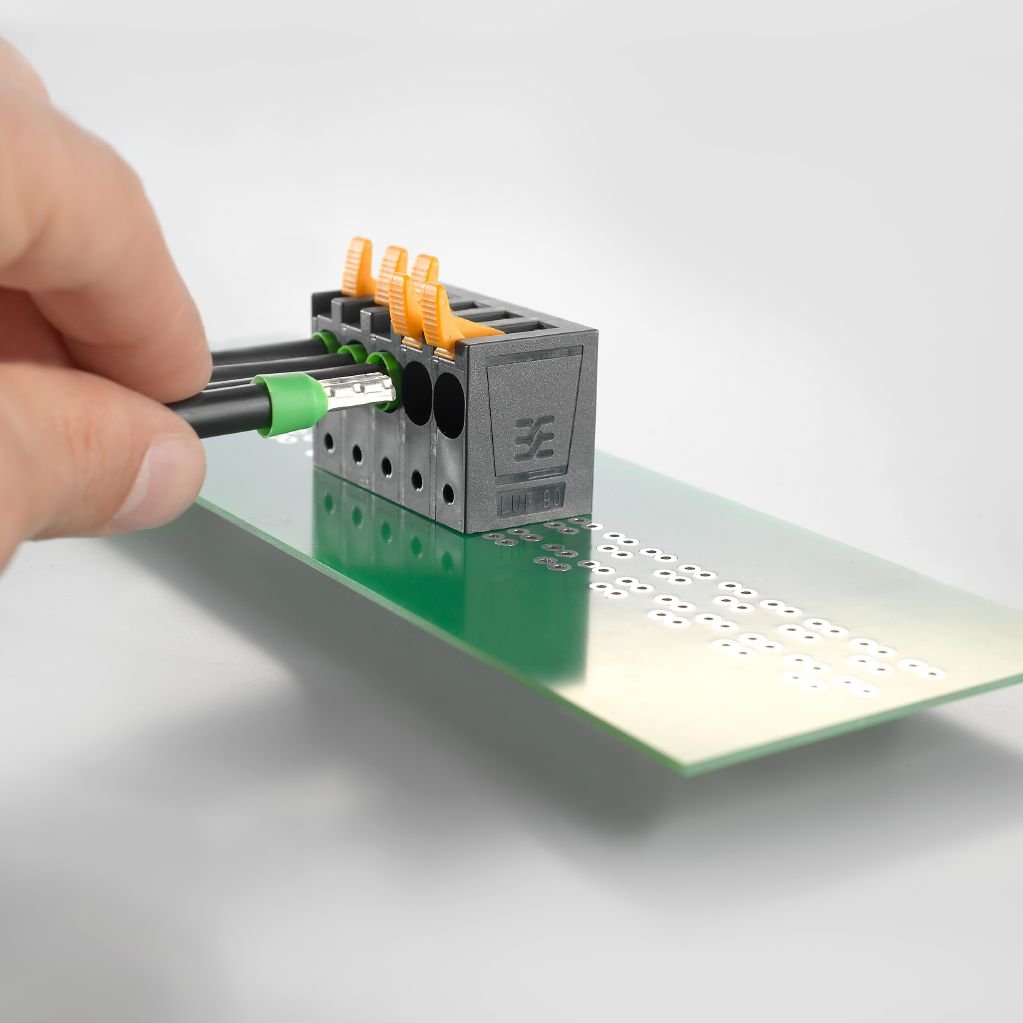

In a nutshell, the LUF system is a PUSH IN direct-insert connection system where the connections have a “pusher” or lever. Wire ends are simply plugged into the contact point without a fuss. In turn, conductors can be easily removed by pressing the “pusher” or actuating the lever. In comparison to conventional connection systems, the direct-insertion system reduces wiring times by up to 80%. I do not know about you, but I would take an extra 48 minutes on the hour to attend to other tasks whether personal or project related.

To meet Dolby’s reliable connection during periods of heavy use (heavy vibration) requirement, the LUF PCB terminals maintain a securely closed contact point via the “Connection Safety Concept*” - where the conductor is always clamped firmly. This is how the proverbial wheels DO NOT fall off when the action packed movie soundtrack crescendos.

Sommerfeld has the final word on the project, “The balance of rugged mechanical & electrical design, ease-of-use, wire compatibility, and cost made the Weidmuller LUF 10.00 a great fit for our new high-performance System 133 & 136 loudspeakers, which will be sold into venues all over the world.”

Closer to home at URS Electronics headquarters in perpetually sunny Portland, Oregon USA, we oft get the concerned query from our customers about ways to hold wires fast in place on PCB boards. Whether it be the board of a fire alarm panel to a “it was due yesterday” robotics project to the control board of their nightmare inducing Furbie – we whole heartedly endorse the sturdy chomp of Weidmuller’s LUF series and extended OMNIMATE interconnects family to address their needs.

Should your project ever be “hanging by a thread”, in this case by wire, make sure it is fastened with a little bit of LUF.

Checkout more on Weidmuller’s LUF 10.00 here, and the full OMNIMATE family here. In addition, feel free to reach out to your friendly, URS Electronics sales representative by calling (503) 233-5341 or reach out by emailing sales@ursele.com for a LUF of interconnection.

*Connection Safety Concept is a method of connection developed by Weidmuller whereby their terminals shut automatically (and remain so) to prevent connection errors.